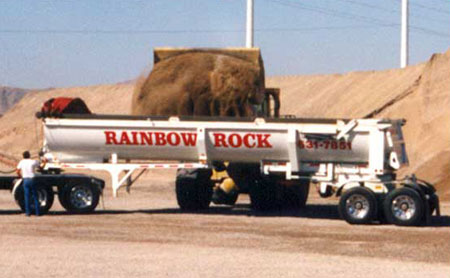

Frameless “Bridger” Half-Round Rock Trailer

Clement’s half-round rock trailer with the popular “Bridger Sliding Tandem”

Clement rock trailers have become the standard against which other trailers are now judged. Whether it’s 14-ton boulders in Ohio, 2-ton rip-rap in Texas, or even shot rock in San Diego, California, Clement rock trailers have handled the loads with efficiency. Clement rock trailers are also adept at handling more conventional loads like sand and gravel, liquid concrete and asphalt. This outstanding track record is the result of Clement’s outstanding engineering and the experience gained from thousands of rock trailers in the field.

Multiple applications Clement’s rock trailers standard body shell with 45-inch sides, is made of 1/4-inch AR400, a very tough steel that makes the trailer capable of withstanding severe impact loads, as well as normally anticipated loads such as sand, gravel, coal, scrap, demolition, etc. With the inclusion of Clement’s patened “Bridger” sliding tandem, much larger payloads are possible with a much shorter trailer.

Features That Set Clement Rock Trailers Apart

Meritor 102-inch, 25,000-lb. axles in combination with hub-piloted wheels

Proven on hundreds of thousands of trailers, 25,000-lb. Meritor axles feature common inner and outer bearings. Combined with Meritor’s parallel spindle, both axle and bearing life are substantially increased. With hub-piloted wheels there are no inner nuts and all nuts have right-hand threads. Maintenance time and costs are reduced

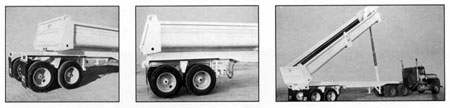

Dumps with wheels on the ground – Clement’s Quarter Frame steel end dump dumps with wheels on the ground. Our Quarter Frame also gives you higher spill points.

Air-Lift gate with 81-inch opening and larger

The Clement Quarter Frame’s standard gate has a minimum 81-inch opening that improves discharge. Mud flaps are attached to the tailgate to reduce flap damage. Barn door tailgates are optional

Clement’s inverted cylinder

With an inverted cylinder there’s no doghouse to interfere with the load. Since the kingpin is located forward, the bridge length is longer allowing greater gross weight. An inverted cylinder has no ledges where dirt can collect and contaminate the system. Because the cylinder is externally mounted, it is easier to service and faster to remove.

The “Bridger” attains maximum legal payloads with proper weight distribution not possible with conventional frametypes.

Simple in Design… To dump the load over the rear tandem, both axles of the trailer are locked. The trailer can then be moved backward, positioning the axles correctly for dumping. After locking the tandem, the trailer can be dumped as any other end dump. The “Bridger” is a viable option for any length Clement frame or frameless end dump trailer.

SPECIFICATIONS

CHASSIS

- Suspension: 50,000 # Single

Point – 3 leaf - Axles: (2) 102″, 25,000 lb, 5″ Round, Common Inner/Outer Bearings

- Wheels: 8.25 x 24.5, 10 Hole Hub-Piloted Disc

- Tires: 11 x 24.5 Radial

10 Hole - Hubs: 10 Hole Pilot Hub

- Brakes: Air 16 1/2″ x 7″ Outboard Cast Drum

- ABS: 2S 1M

- Axle Spacing: 51inch

- Lights: 12 Volt Sealed Beam, Rubber Grommet

- Wiring: Sealed Harness Modular Plug In

- Mud Flaps: Rubber Rear Only

- King Pin Plate: 1/4″ AR400 (Rocking/Breakaway)

- Back-up Alarm: Yes

BODY

- Type: Steel Type 1/2 Round Dump for rip rap, rock or demolition

- Body Shell: 1/4 -inch AR400 Abrasion Resistance Steel (alternate body thickness or side height available)

- Tailgate: Top Hinged, Air Lift 1/4 inch AR400 Abrasion Resistance Steel

- Front: 1/4 inch AR450

- Paint: One color urethane enamel over primed surface

- Longitudinals: None

- Top Rail: 3/16-formed angle shedder

- Side Braces: 1/4 inch HT50

- Hoist Housing: None, inverted Trunion Mount Hoist