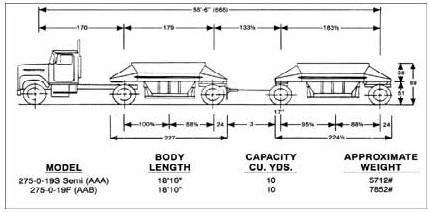

West Coat Trains Steel Bottom Hopper

Engineered to provide an optimum return on your investment!

Big, rugged hoppers ideal for general contractingIdeally suited for general contracting These big, rugged Clement Monoshell hopper trains carry a total of 20.5 cubic yards. Hi-tensile, all-welded Mono-Shell construction means greater durability … less dead-weight. You haul bigger legal loads of aggregate, sand, fill … and dump them faster. Built to take the abuse of rough loading, Clement Mono-Shell trains are equipped with air-powered clam shell gates. Dumping is quick … cleanout complete. Only the Clement Monoshell gives you … Biggest Payloads — Mono-Shell design takes weight out of the equipment … puts it in the payload. • Faster Operation — No cross bracing to slow up loading … no interior projection. Steep, smooth sides mean faster, complete cleanout. • Lowest Maintenance — Clement engineering combines simplicity and ruggedness in a field-tested, customer-proved design • Longer-Life — The stronger, lighter mono-shell design combined with exclusive stress-flex mounting eliminates the rigidity of truss-frame trailers. The Monoshell’s air-powered gates meet your every requirement

|

|||||||

|

|||||||

Chassis

Suspension: 22,000#

Axles: (2) 22,500#

Whells: 8.25 x 24.5 Disc

Tires: 11.00 x 24.5 Bias

Brakes: Air 16-1/2 x 7 inch Cast Drum

Lights: Sealed Beam, Turn signals rear both trailers

Wiring: Sealed Harness 7 wire ATA, Sep. Gate Circuit

Mud Flaps: Rear Only

King Pin Plate: 1/4-inch HT50- Fixed

Turn Table: 39-inch Double Ballbearing

Pintle Eye: Swivel

Draw Bar: Tubular, Rubber Bushed hinge

Type: For windrowing aggregates, dirt, base or any granular free flowing material work

Design: Monoshell

Upper Skins: 14 Gauge HT50

Lower Skins: 12 Gauge HT50

Gate Throat: 3/16-inch HT100

Gate Plate: 3/16 gauge HT100

King Pin Location: 14-inch (Max tractor 5th wheel 8″)

Paint: One color urethane over cleaned, phosphatized and primed surface

Slopes: side-70 end-55

Ground Clearance Undergate: 17-inch open – 14-inch closed

Discharge Gate: One 44 x 69-inch air powered clambshell adjustable spreader chains, twin 6-inch air-cylinders

Air Reservoir: 6,800 cubic in.

Gate Controls: Side body mounted neutral hold, hand or electric operated

Clement’s air-powered clamshell gates work faster, permit on-the-go discharge. Actuated by large, twin 6-inch double-acting cylinders, gates can be stopped and held at any position … readily closed against the load. The dumping rate is controlled by opening the gate to any desired position … spreader chains positively position the gates for laying windrows. Just one valve opertes the air-powered gate. The valve is located conveniently at the side of the body. Optional in-cab controls permit the gate to operate from the cab or the trailer. Meets all ICC regulations … safety regulator maintains brake pressure under emergencies.

Clement’s air-powered clamshell gates work faster, permit on-the-go discharge. Actuated by large, twin 6-inch double-acting cylinders, gates can be stopped and held at any position … readily closed against the load. The dumping rate is controlled by opening the gate to any desired position … spreader chains positively position the gates for laying windrows. Just one valve opertes the air-powered gate. The valve is located conveniently at the side of the body. Optional in-cab controls permit the gate to operate from the cab or the trailer. Meets all ICC regulations … safety regulator maintains brake pressure under emergencies.