JobStar Steel Bottom Hopper Dump Trailer

Engineered to provide an optimum return on your investment!

Clement utilized computer “finite element analysis (F.E.A.)” to develop an extremely strong, relatively light weight dump trailer that was quite simple to manufacture. The results of which offer the customer a “workhorse trailer” and long life at a reasonable price.

Evidence of the strength built into the dump trailer are the 3/16″ HT50 high tensile steel side sheets assuring extended life expectancy when compared to other trailers. Supporting these heavy duty side sheets are two massive 4″ x 6″ tube bottom rails with 4″ x 6″ bracing.

Another innovative feature built into the Clement is utilizing the bottom rails as our 80 gallon air tank for the gate, eliminating cost and weight.

Finally as with all Clement dump trailers, our foundation is strong and stable with 102″ 25,000 pound axles; common inner and outer bearings; a 40,000 pound four-spring suspension as standard with 50,000 pound single point as an option.

THE NEW CLEMENT JOBSTAR… LOADS FAST, HAULS MORE, DUMPS DEPENDABLY

Front view of JobStar’s extremely strong clamshell gate, closed with its massive externally mounted 8pinch diameter cylinders.

duty timing gear

Front view of the extra heavy-duty timing gear that never needs replacing, adjusting or maintenance. Also illustrated is the positive five-position gate positioning bar.

JobStar’s 80-gallon

JobStar’s 80-gallonair tank in the bottom rail

Clement’s innovative air tank eliminates the weight of an extra tank. At the same time it provides an early warning in the event that this vital member is damaged and requires immediate repair.

The muscle of the JobStar –

the hopper

The hopper with 3/16-inch Hiten-50 steel as standard is nearly double that of competitive units, thus you get double the wear. As an option, 3/16-inch AR450 abrasion resistant steel is available to further increase the life of the trailer.

Infinite Gate Control

Clement’s gate control ground station puts total infinite metering control into the hands of the ground operator. JobStar’s ground control also allows total hands-free operation not available on most competitive trailers. Pushing the palm button activates Clement’s hands-free infinite gate control, or to stop the gate at an infinite number of positions by centering the lever. Once the lever is positioned, the operator may remove his hands for a total hands-free operation! Last, but not least, is hands-free feathering.

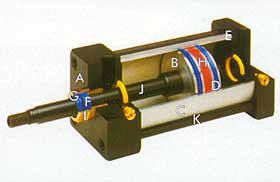

Clement Air Cylinder Cross Sections and Features

B. Piston machined from solid aluminum bar stock

C. Hard anodized ID aluminum tube

D. Lip-type low friction urethane piston seals are pressure-energized.

E. Nitrile O-ring design is pressure compensated and reusable.

F. Rod lip seals with a rod u-cup is completely self compensating for zero leakage at all pressures.

G. The new wiper wipes dirt out for less maintenance.

I. Bronze gland is externally removable without cylinder disassembly for easy maintenance.

J. Piston rod high steel. Nitrocarburizing treatment on the rod gives better corrosion-resistance properties (outperforms 12-micron (.0005 inches) Chromium electroplating by ratio up to 20:1).

K. Tie rods have corrosion resistant (Nitro carburizing)., stress proof steel.

SPECIFICATIONS

- 20 yards, no boards

- 22.5 with boards

Dimensions:

- 40 ft. overall length, w/o push bar

- 102-inch overall width

- 114-inch height w/o boards

- 193 x 90-inch hopper opening

- 111 x 55-inch gate opening

- Ground clearance under gate:

- 17-inches w/ 24.5-inch tires

- 16-inches w/ 22.5-inch tires

Body:

- 3/16-inch hopper skins throughout

- 79° hopper side slope

- 55° hopper end slope

- 90° slope lower hopper

- 4 x 6-inch bottom rail

- 4 x 6-inch top rail and braces

- Rear fenders standard

Gate:

- 3/16-inch high tensile steel floor

- 8-inch externally mounted cylinders

- 80-gallon air tank in bottom rail

- Infinite gate positioning and feathering control

- Automatic injection air lubricator

- Sealed beam, 7-way conduit in rubber grommets

- Separate gate circuit

Running gear:

- Axles: 102-inch – 5-inch round 25K capacity

- Bearings: Common inner and outer

- Suspension:

- Std: 44,000#, 4 spring – 3 leaf

- Opt: 50,000# single point

- Wheels: 10-hole hub piloted disc, 8.25 x 24.5

- Brakes: 16-1/2 x 7-inch fast change

- Drums: Outboard cast

- Tires: 11R 24.5 radials

- ABS: 2S – 1M standard

Paint:

Premium epoxy primer. Urethane finish for excellent durability

Weight:

12,900 pounds with 4-spring